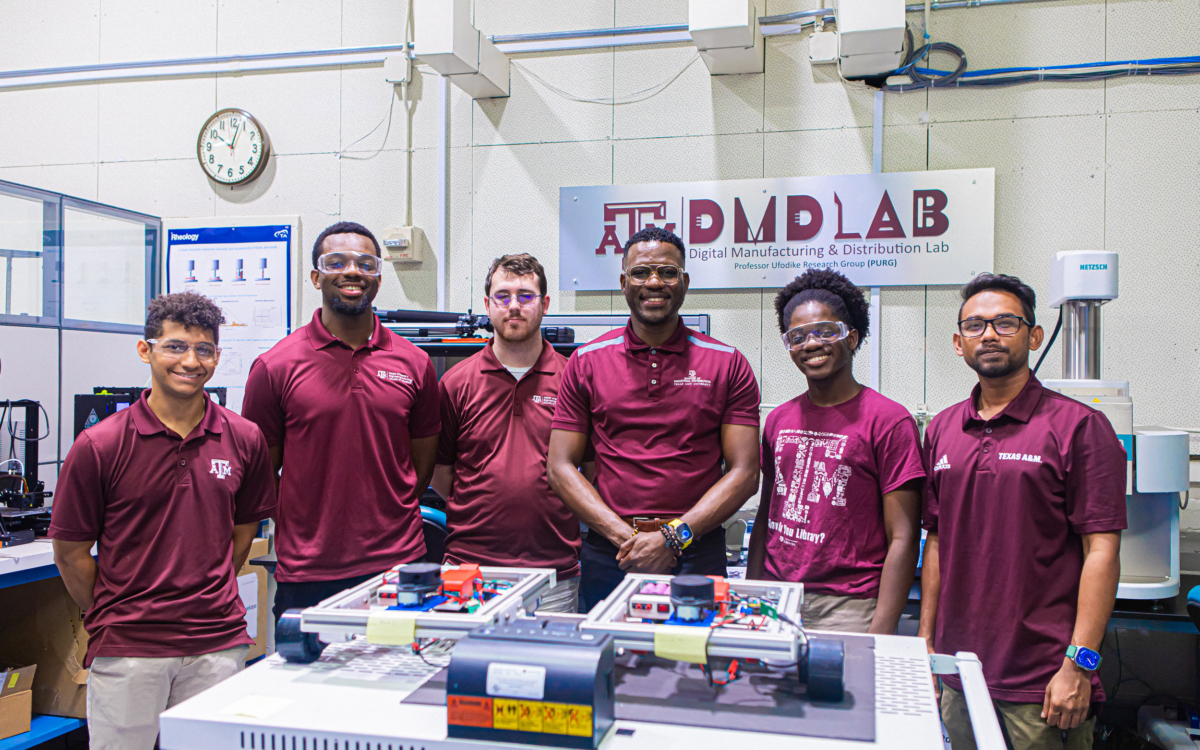

Welcome to the DMD-Lab

The Digital Manufacturing and Distribution Lab (DMD-Lab) is the innovation hub of the Professor Ufodike Research Group (PURG) at Texas A&M University. We bring together cutting-edge research, student training, and industry collaboration to push the boundaries of:

- AI-driven additive manufacturing

- Predictive materials design

- Smart distribution technologies

Our mission is to serve as a bridge between academic discovery and real-world application, preparing the next generation of engineers to lead the transformation of U.S. manufacturing and distribution in a digital-first world.

What We Do

- AI-Enhanced Additive Manufacturing: physics-aware, closed-loop FFF/AM

- Process Systems & Smart Factories: sensing, control, and optimization

- Distribution Analytics: data-driven decisions for operations and inventory

- Test & Measurement: rigorous experimental design and validation

Our Mission

To advance intelligent manufacturing and distribution through rigorous research, hands-on education, and industry collaboration—equipping graduates and partners to build, scale, and sustain modern production systems.

What Makes DMD-Lab Different

- Modeling + Experimentation: high-fidelity simulation paired with instrumented experiments and structured DoE.

- Curriculum ↔ Industry Loop: research insights directly integrated into MMET 301 (Mechanical Power Transmission) and IDIS 450 (Analytics for Distribution Operations), then field-tested with partners.

- Publication to Practice: translating peer-reviewed research into deployable toolkits, methods, and training for plant and field teams.

Where We Work

- DMD-Lab (THOM 104A): additive manufacturing, sensing, controls, materials testing

- Power Technology Laboratory (THOM 009B): hands-on mechanical drives, hydraulics/pneumatics, and diagnostics used in MMET 301

Collaboration Programs

- Capstone & Internships: scoped projects with student teams and faculty oversight

- Industry Sprints (4–8 weeks): focused studies (AM process tuning, energy loss in drives, inventory analytics)

- Consortia: launching the Lean Distribution Excellence Consortium (LDEC) to advance best practices in distribution operations

Facilities & Expertise

Our labs are equipped with rheometers, FTIR, confocal microscopes, and multi-format 3D printers, supported by a team experienced in AI integration, machining, and fluid mechanics.

Get Connected

- For Students: Interested in research? Join us as a PhD/MS candidate, postdoc, or undergraduate assistant.

- For Industry Partners: Explore short-term pilots, guest lectures, or year-round collaborations.

- For Collaborators: Let’s co-create competitive proposals and applied platforms together.

Publications

- Ufodike, Chukwuzubelu Okenwa, Gaius Chukwuka Nzebuka, and Al Mazedur Rahman. “Combine effect of feeding rate and modeling parameter on the extrusion pressure in material extrusion additive manufacturing.” Manufacturing Letters 35 (2023): 485-492. https://doi.org/10.1016/j.mfglet.2023.07.007

- Ufodike, Chukwuzubelu Okenwa, Gaius Chukwuka Nzebuka*, and Chijioke Peter Egole. “Prediction of Limiting Casting Speed in a Horizontal Direct-Chill Casting through Numerical Modeling and Simulation.” Metals 13.6 (2023): 1071. https://doi.org/10.3390/met13061071

- Rahman, Al Mazedur*, Taieba Tuba Rahman, Zhijian Pei, Chukwuzubelu Okenwa Ufodike, Jaesung Lee, and Alaa Elwany. “Additive Manufacturing Using Agriculturally Derived Biowastes: A Systematic Literature Review.” Bioengineering 10, no. 7 (2023): 845. https://doi.org/10.3390/bioengineering10070845

- Nzebuka, Gaius Chukwuka*, Chukwuzubelu Okenwa Ufodike, Al Mazedur Rahman*, Chavous Maurice Gwynn*, and Mohammad Faisal Ahmed. “Numerical modeling of the effect of nozzle diameter and heat flux on the polymer flow in fused filament fabrication.” Journal of Manufacturing Processes 82 (2022): 585-600. https://doi.org/10.1016/j.jmapro.2022.08.029

- Rahman, Al Mazedur*, Abhinav Bhardwaj, Zhijian Pei, Chukwuzubelu Ufodike, and Elena Castell-Perez. 2022. “The 3D Printing of Biomass–Fungi Composites: Effects of Waiting Time after Mixture Preparation on Mechanical Properties, Rheological Properties, Minimum Extrusion Pressure, and Print Quality of the Prepared Mixture” Journal of Composites Science 6, no. 8: 237 (2022). https://doi.org/10.3390/jcs6080237

- Ufodike, Chukwuzubelu Okenwa, and Gaius Chukwuka Nzebuka*. “Investigation of thermal evolution and fluid flow in the hot-end of a material extrusion 3D Printer using melting model.” Additive Manufacturing 49 (2022): 102502. https://doi.org/10.1016/j.addma.2021.102502

- Ufodike, Chukwuzubelu Okenwa, and Grzegorz Dolzyk. “Crashworthiness of Circular Tubes with Rhombus Star Grooving Pattern.” Materials Today Communications 29 (2021): 102899. https://doi.org/10.1016/j.mtcomm.2021.102899

- Nzebuka, Gaius Chukwuka*, Chukwuzubelu Okenwa Ufodike, and Chijioke Peter Egole. “Influence of various aspects of low-Reynolds number turbulence models on predicting flow characteristics and transport variables in a horizontal direct-chill casting.” International Journal of Heat and Mass Transfer 179 (2021): 121648. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121648

- Ufodike, Chukwuzubelu Okenwa, Mohammad Faisal Ahmed, and Grzegorz Dolzyk. “Additively manufactured biomorphic cellular structures inspired by wood microstructure.” Journal of the Mechanical Behavior of Biomedical Materials 123 (2021): 104729. https://doi.org/10.1016/j.jmbbm.2021.104729

- Ufodike, Chukwuzubelu Okenwa, Hui Wang, Mohammad Faisal Ahmed, Grzegorz Dolzyk, and Sungmoon Jung. “Design and modeling of bamboo biomorphic structure for in-plane energy absorption improvement.” Materials & Design 205 (2021): 109736. https://doi.org/10.1016/j.matdes.2021.109736

- Ufodike, Chukwuzubelu Okenwa, Vincent Obiozo Eze, Mohammad Faisal Ahmed, Abiodun Oluwalowo, Jin Gyu Park, Okenwa I. Okoli, and Hui Wang. “Evaluation of the inter-particle interference of cellulose and lignin in lignocellulosic materials.” International journal of biological macromolecules 147 (2020): 762-767. https://doi.org/10.1016/j.ijbiomac.2020.01.234

- Ufodike, Chukwuzubelu Okenwa, Vincent Obiozo Eze, Mohammad Faisal Ahmed, Abiodun Oluwalowo, Jin Gyu Park, Zhiyong Liang, and Hui Wang. “Investigation of molecular and supramolecular assemblies of cellulose and lignin of lignocellulosic materials by spectroscopy and thermal analysis.” International journal of biological macromolecules 146 (2020): 916-921.https://doi.org/10.1016/j.ijbiomac.2019.09.214

- Ufodike, Chukwuzubelu, Sean Jackson, Nydeia Bolden, and Tarik Dickens. “Synthesis and characterization of extruded cellulosic fibrils for enhanced reinforced/filamentary textiles.” Textile Research Journal 88, no. 5 (2018): 520-531.https://doi.org/10.1177/0040517516681964