Discover Our Contributions to Advancing Knowledge

Welcome to the Publications page of the Digital Manufacturing and Distribution Lab (DMD-Lab). Here, we proudly showcase the wealth of knowledge, innovation, and insights generated by our team. Our commitment to pushing the boundaries of digital manufacturing is evident in the quality and impact of our publications.

DMD-Lab’s researchers are at the forefront of groundbreaking discoveries, contributing to peer-reviewed journals, conferences, and other scholarly outlets. From the intricacies of additive manufacturing to the complexities of material science, our publications span a diverse array of topics, reflecting the multidisciplinary nature of our research.

Explore our publications to gain insights into the latest advancements, methodologies, and findings in the realm of digital manufacturing. Whether you are an academic, industry professional, or an enthusiast eager to delve into the forefront of manufacturing research, our publications offer a window into the innovative work happening at DMD-Lab.

Join us on a journey of intellectual exploration, where each publication represents a step forward in our mission to transform manufacturing through cutting-edge research. Our commitment to sharing knowledge is a testament to our belief in the power of collaborative learning and the impact it can have on shaping the future of manufacturing.

PUBLICATIONS – https://orcid.org/0000-0001-5718-0661 (* indicates students and postdocs, — year split)

2023

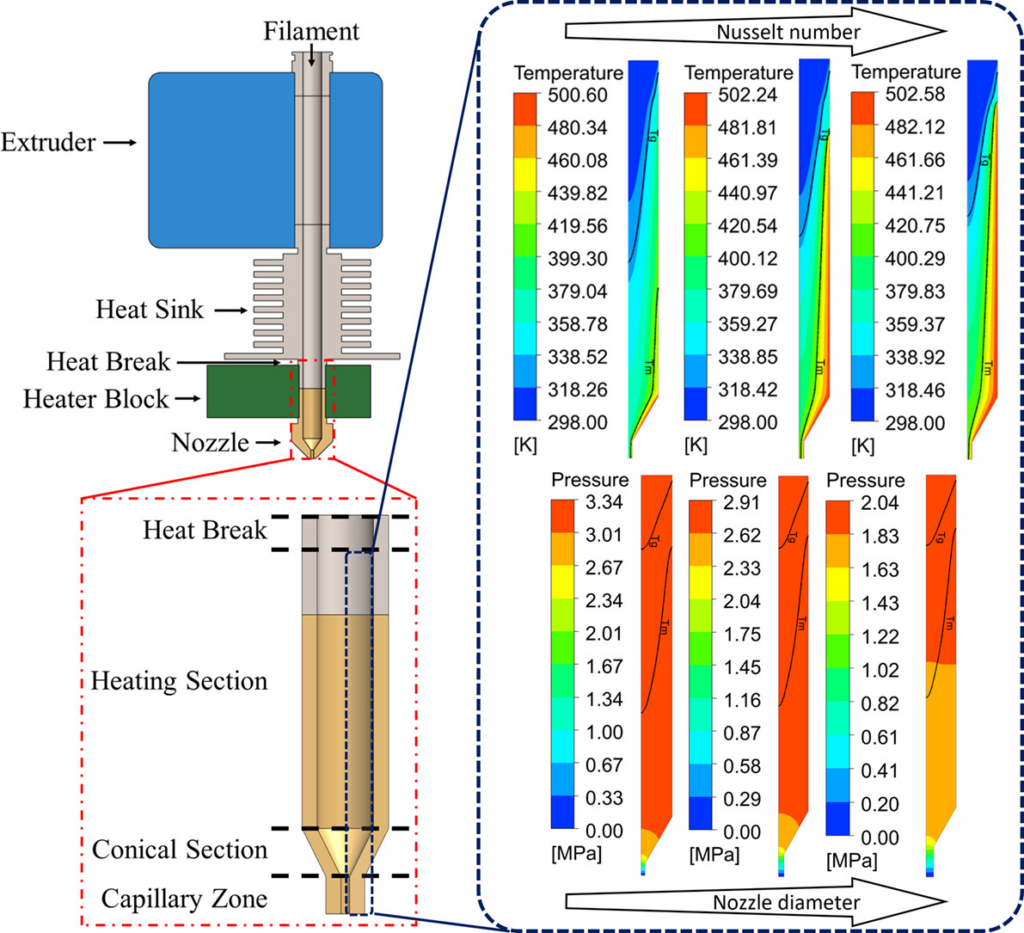

Ufodike, Chukwuzubelu Okenwa, Gaius Chukwuka Nzebuka, and Al Mazedur Rahman. “Combine effect of feeding rate and modeling parameter on the extrusion pressure in material extrusion additive manufacturing.” Manufacturing Letters 35 (2023): 485-492. https://doi.org/10.1016/j.mfglet.2023.07.007

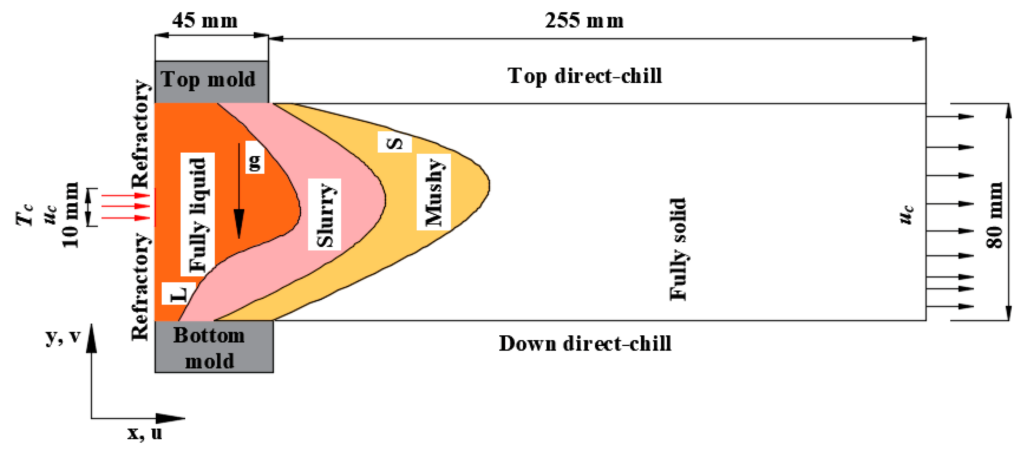

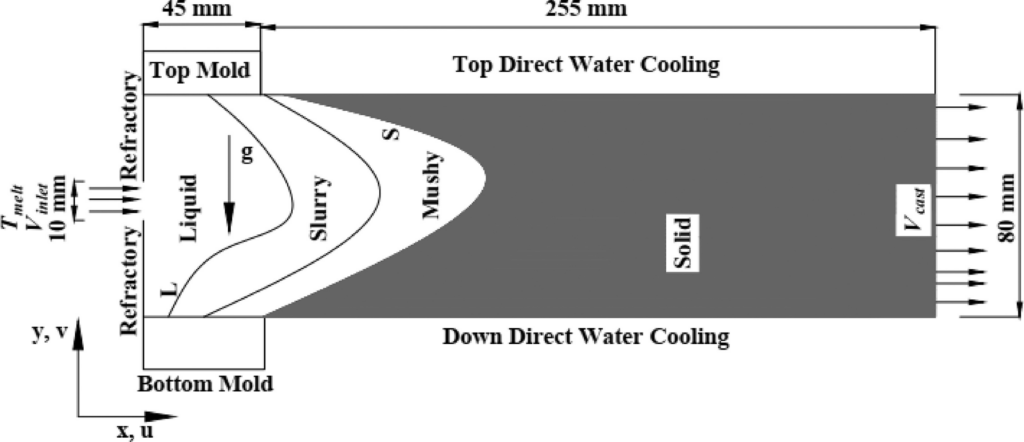

Ufodike, Chukwuzubelu Okenwa, Gaius Chukwuka Nzebuka*, and Chijioke Peter Egole. “Prediction of Limiting Casting Speed in a Horizontal Direct-Chill Casting through Numerical Modeling and Simulation.” Metals 13.6 (2023): 1071. https://doi.org/10.3390/met13061071

Rahman, Al Mazedur*, Taieba Tuba Rahman, Zhijian Pei, Chukwuzubelu Okenwa Ufodike, Jaesung Lee, and Alaa Elwany. “Additive Manufacturing Using Agriculturally Derived Biowastes: A Systematic Literature Review.” Bioengineering 10, no. 7 (2023): 845. https://doi.org/10.3390/bioengineering10070845

2022

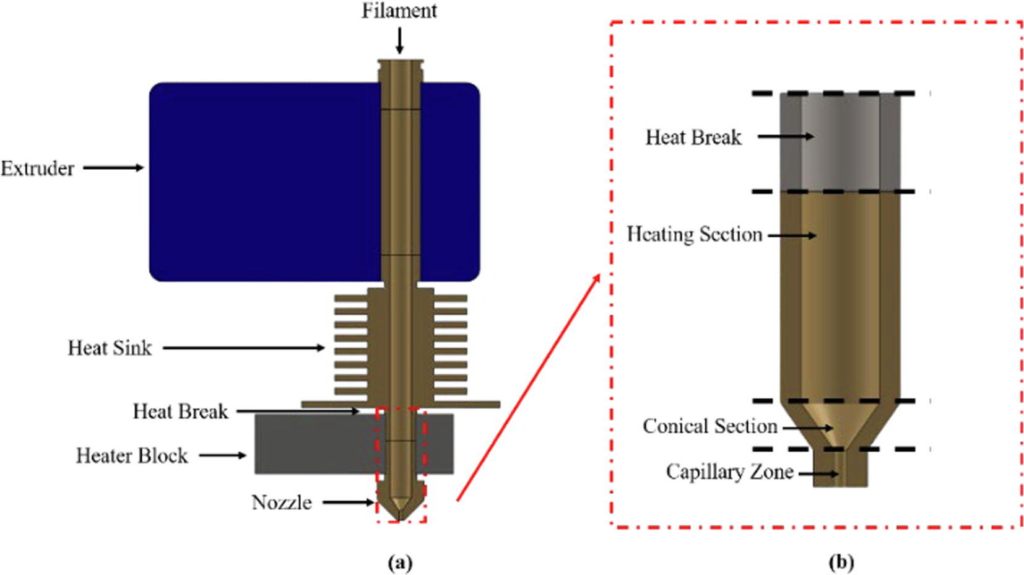

Nzebuka, Gaius Chukwuka*, Chukwuzubelu Okenwa Ufodike, Al Mazedur Rahman*, Chavous Maurice Gwynn*, and Mohammad Faisal Ahmed. “Numerical modeling of the effect of nozzle diameter and heat flux on the polymer flow in fused filament fabrication.” Journal of Manufacturing Processes 82 (2022): 585-600. https://doi.org/10.1016/j.jmapro.2022.08.029

Rahman, Al Mazedur*, Abhinav Bhardwaj, Zhijian Pei, Chukwuzubelu Ufodike, and Elena Castell-Perez. 2022. “The 3D Printing of Biomass–Fungi Composites: Effects of Waiting Time after Mixture Preparation on Mechanical Properties, Rheological Properties, Minimum Extrusion Pressure, and Print Quality of the Prepared Mixture” Journal of Composites Science 6, no. 8: 237 (2022). https://doi.org/10.3390/jcs6080237

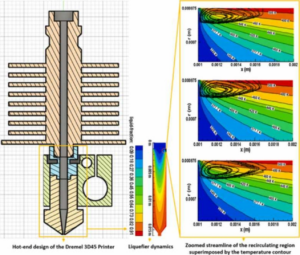

Ufodike, Chukwuzubelu Okenwa, and Gaius Chukwuka Nzebuka*. “Investigation of thermal evolution and fluid flow in the hot-end of a material extrusion 3D Printer using melting model.” Additive Manufacturing 49 (2022): 102502. https://doi.org/10.1016/j.addma.2021.102502

2021

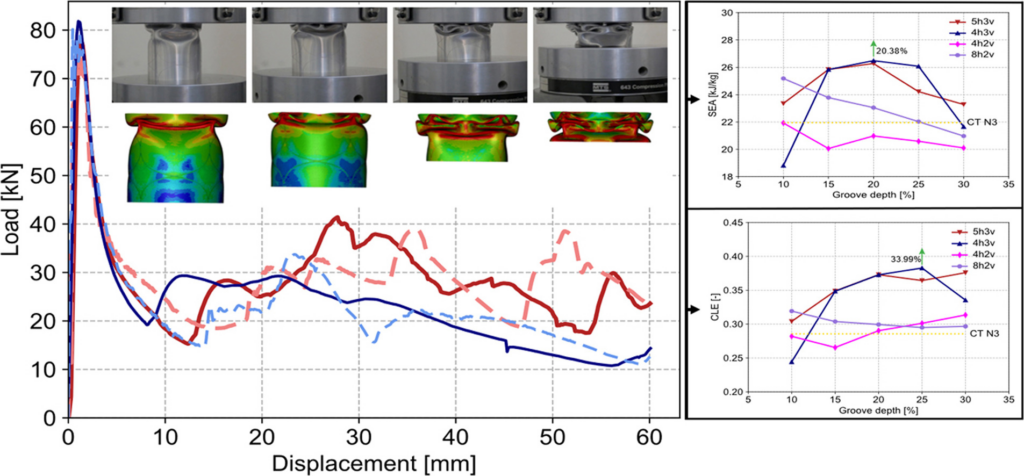

Ufodike, Chukwuzubelu Okenwa, and Grzegorz Dolzyk. “Crashworthiness of Circular Tubes with Rhombus Star Grooving Pattern.” Materials Today Communications 29 (2021): 102899. https://doi.org/10.1016/j.mtcomm.2021.102899

Nzebuka, Gaius Chukwuka*, Chukwuzubelu Okenwa Ufodike, and Chijioke Peter Egole. “Influence of various aspects of low-Reynolds number turbulence models on predicting flow characteristics and transport variables in a horizontal direct-chill casting.” International Journal of Heat and Mass Transfer 179 (2021): 121648. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121648

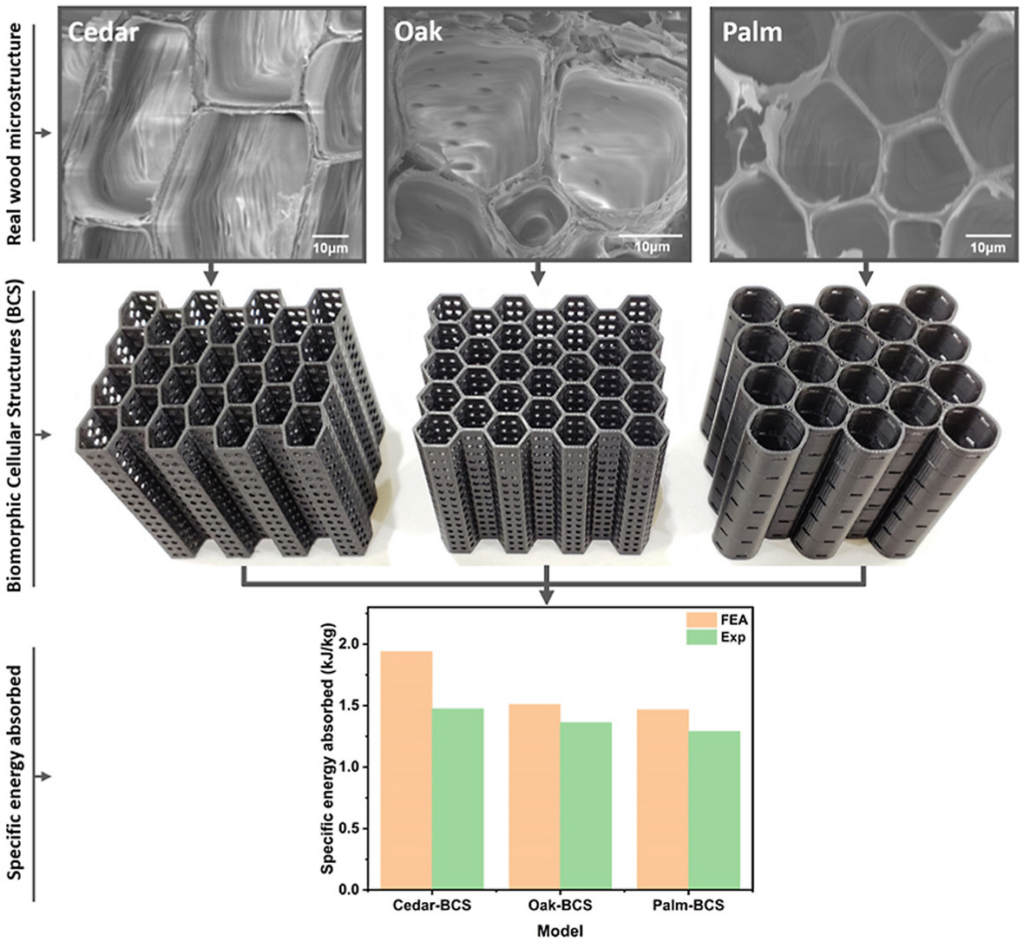

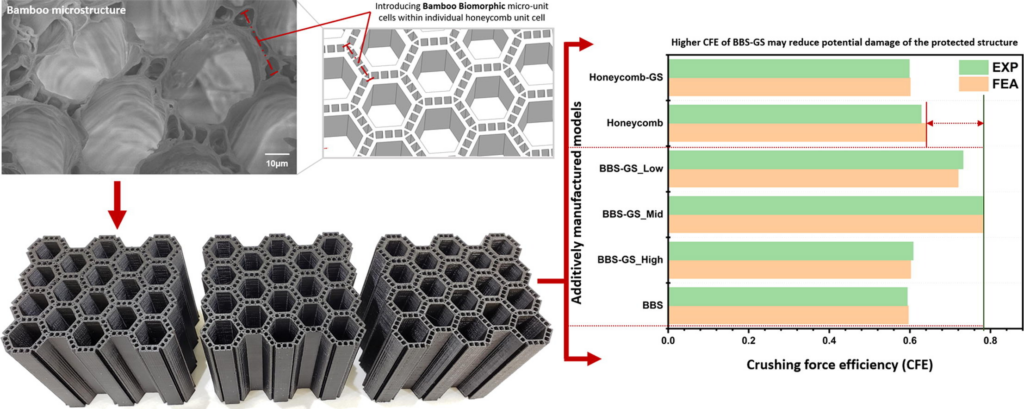

Ufodike, Chukwuzubelu Okenwa, Mohammad Faisal Ahmed, and Grzegorz Dolzyk. “Additively manufactured biomorphic cellular structures inspired by wood microstructure.” Journal of the Mechanical Behavior of Biomedical Materials 123 (2021): 104729. https://doi.org/10.1016/j.jmbbm.2021.104729

Ufodike, Chukwuzubelu Okenwa, Hui Wang, Mohammad Faisal Ahmed, Grzegorz Dolzyk, and Sungmoon Jung. “Design and modeling of bamboo biomorphic structure for in-plane energy absorption improvement.” Materials & Design 205 (2021): 109736. https://doi.org/10.1016/j.matdes.2021.109736

2020

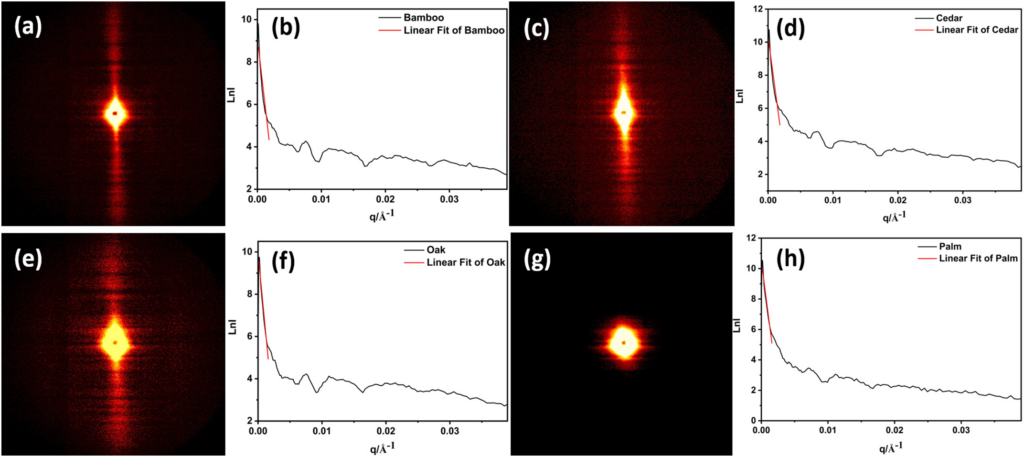

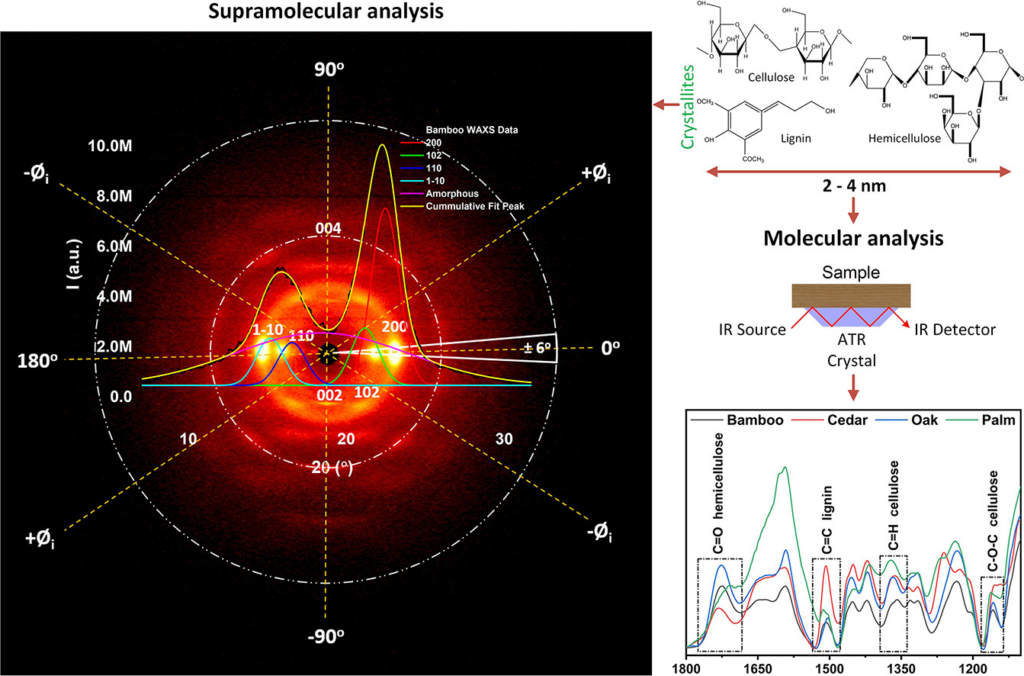

Ufodike, Chukwuzubelu Okenwa, Vincent Obiozo Eze, Mohammad Faisal Ahmed, Abiodun Oluwalowo, Jin Gyu Park, Okenwa I. Okoli, and Hui Wang. “Evaluation of the inter-particle interference of cellulose and lignin in lignocellulosic materials.” International journal of biological macromolecules 147 (2020): 762-767. https://doi.org/10.1016/j.ijbiomac.2020.01.234

Ufodike, Chukwuzubelu Okenwa, Vincent Obiozo Eze, Mohammad Faisal Ahmed, Abiodun Oluwalowo, Jin Gyu Park, Zhiyong Liang, and Hui Wang. “Investigation of molecular and supramolecular assemblies of cellulose and lignin of lignocellulosic materials by spectroscopy and thermal analysis.” International journal of biological macromolecules 146 (2020): 916-921. https://doi.org/10.1016/j.ijbiomac.2019.09.214

2018

Ufodike, Chukwuzubelu, Sean Jackson, Nydeia Bolden, and Tarik Dickens. “Synthesis and characterization of extruded cellulosic fibrils for enhanced reinforced/filamentary textiles.” Textile Research Journal 88, no. 5 (2018): 520-531. https://doi.org/10.1177/0040517516681964