Key Research Area: AI-Enhanced Adaptive Additive Manufacturing for Precision Engineering

Welcome to the heart of innovation. Our research at the DMD-Lab is focused on pushing the boundaries of what’s possible in the realm of advanced manufacturing, with a particular emphasis on AI-Enhanced Adaptive Additive Manufacturing for Precision Engineering.

Overview:

The research in AI-Enhanced Adaptive Additive Manufacturing for Precision Engineering seeks to revolutionize the additive manufacturing landscape by integrating artificial intelligence (AI) into the process. This fusion of AI with physics-infused computational simulation aims to create a dynamic and adaptive manufacturing system that responds intelligently to variations in material behavior and process conditions.

Research Thrusts:

- AI-Infused Control Systems: Explore the integration of artificial intelligence into additive manufacturing processes, creating intelligent control systems that adapt in real-time.

- Material Design Optimization: Investigate the intricate interplay between material properties and process parameters, utilizing AI for advanced material design optimization.

- Defect Inspection Technologies: Develop AI-driven defect recognition and classification techniques for real-time identification and correction of defects during the manufacturing process.

- Application Across Diverse Processes: Apply our transformative framework to various additive manufacturing processes, including FDM/FFF, sheet lamination, VAT polymerization, and PBF.

Research Impact:

Our research doesn’t just stay within the walls of the lab; it’s a driving force for change in the manufacturing landscape. By actively engaging with industry partners, publishing in reputable journals, and commercializing our innovations, we aim to influence the way we approach manufacturing and distribution.

“Explore our research initiatives and join us in shaping the future of manufacturing through innovation, education, and collaboration” – Prof. Chukwuzubelu Ufodike

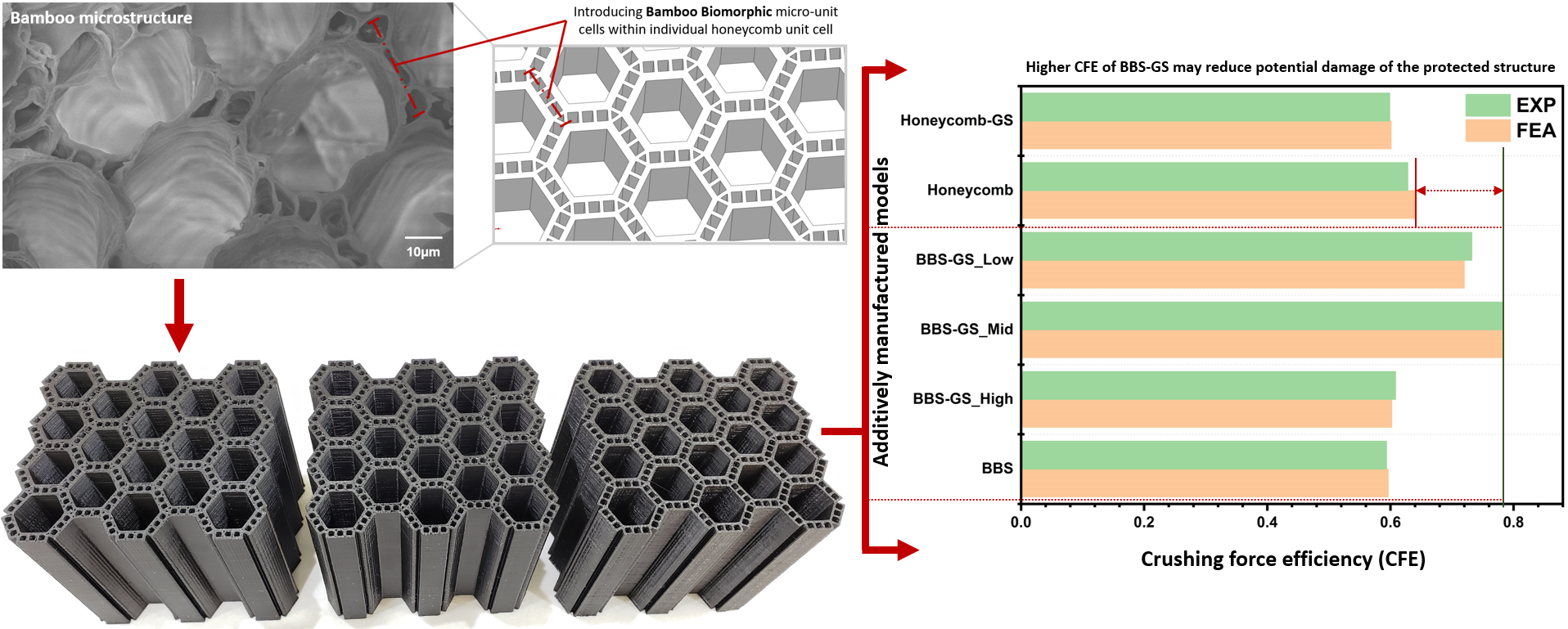

Smart Packaging and Energy Absorbing Materials for Freight Distribution

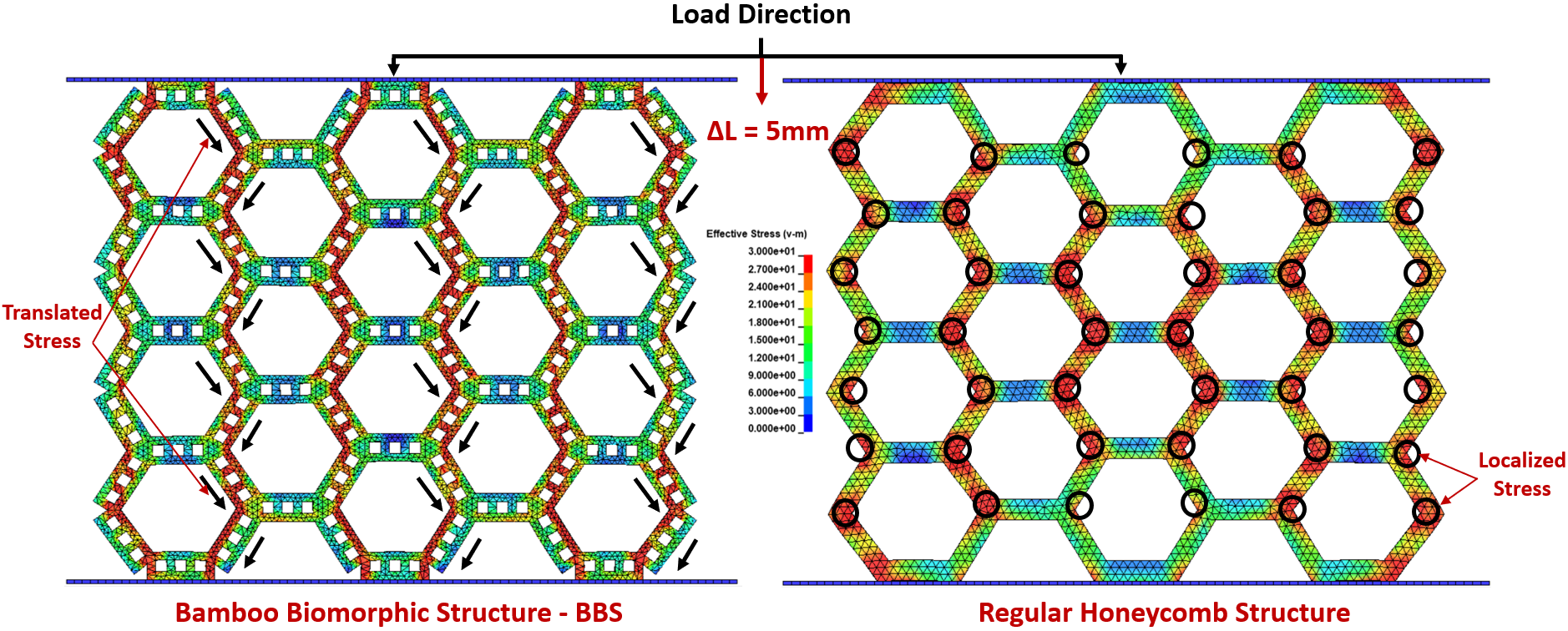

BBS is an adaptive pro-isotropic, high SEA metamaterial that overcomes the uncertainty of knowing the impact direction.

The metamaterial is currently being developed by integrating an adaptive system through AI, for 3D sensing and impact optimization during crash.

Applications: Aerospace, Automotive industry, Packaging materials.

Predictive Theoretical and Computational Framework for Manufacturing & Distribution

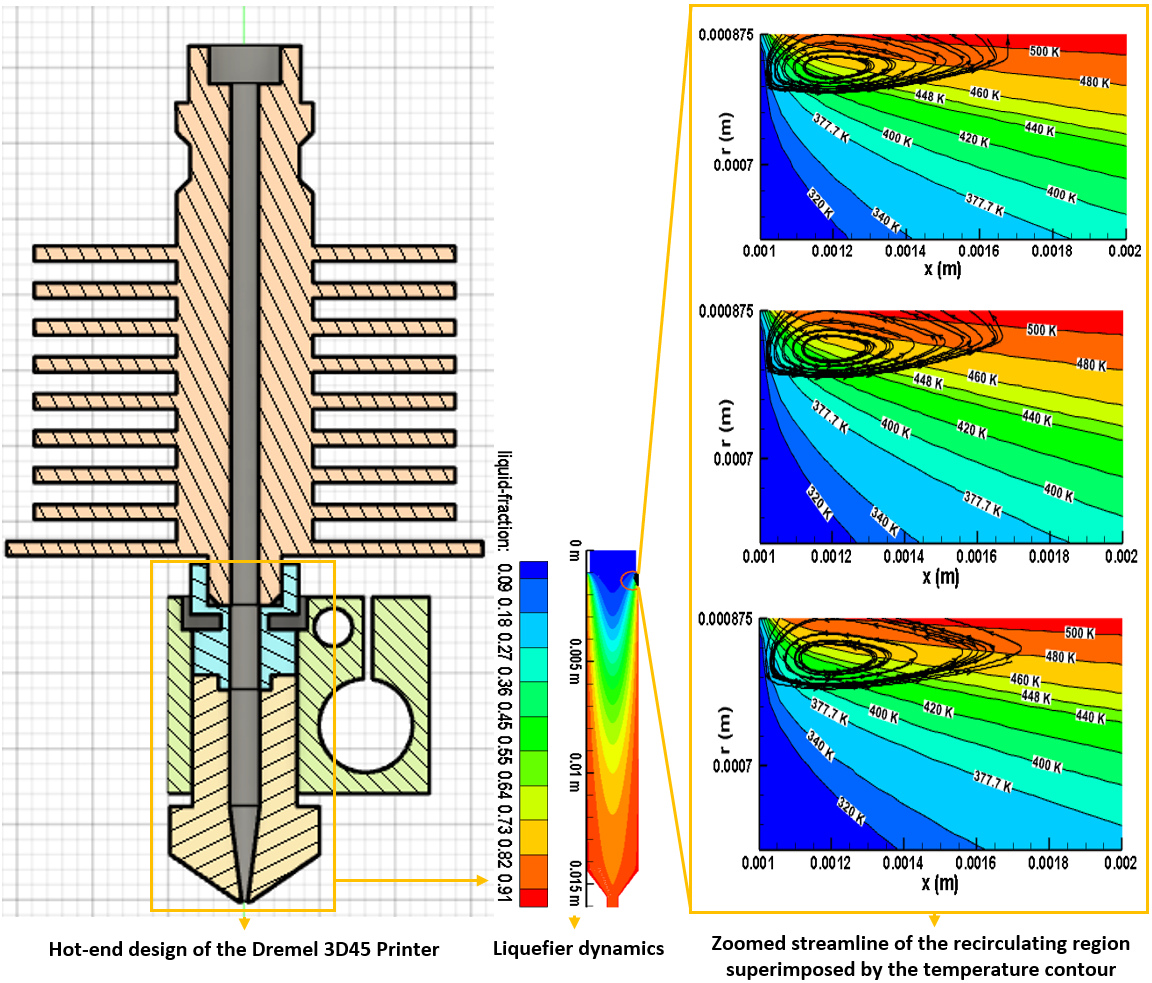

Development of Melting Model for Fused Filament Fabrication (FFF) Additive Manufacturing (AM) Process

The new CFD melting model as applied on the 3D FFF printer in the present study proves to be a powerful tool to easily implement the effect of the air gap between the filament and the liquefier wall.

Such information is very useful to the design engineers and improves the understanding of the coupled heat transfer and fluid flow in the FFF 3D printer hot-end.

Development of Predictive Turbulence Models in HDC casting

Developed CDF Turbulence models in a horizontal direct-chill (HDC) casting solidification system for predicting flow characteristics and transport variables.